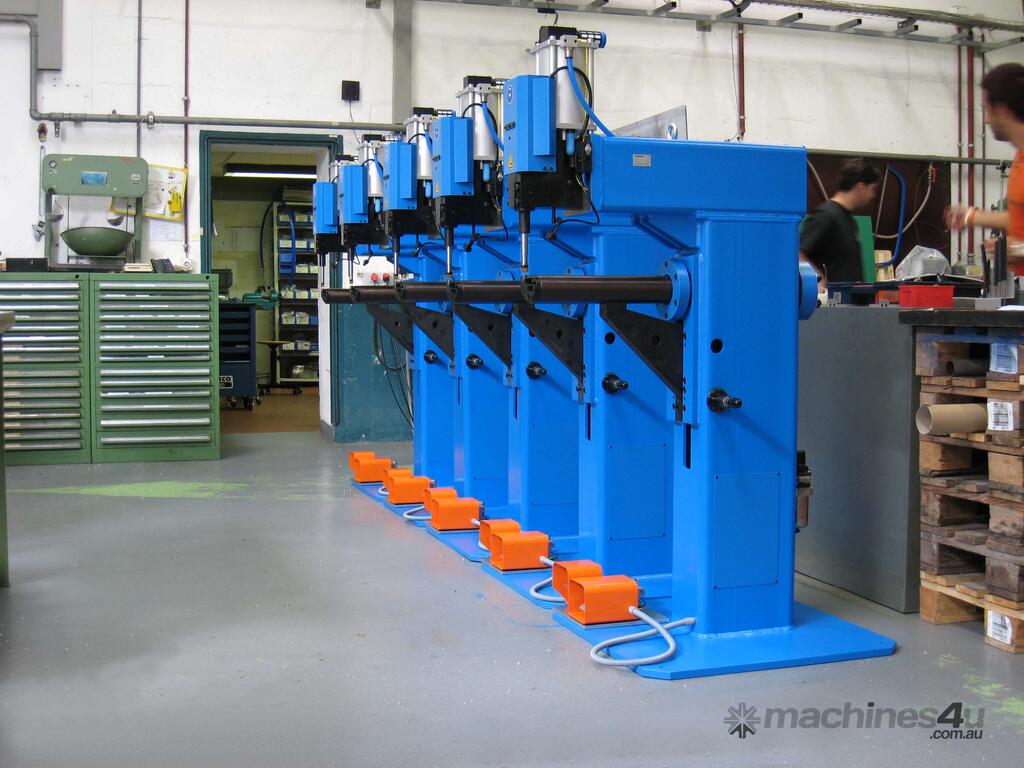

Clinching Machine with no fasteners

Clinching Machine with no fasteners : $26,500 AUD ($29,150 Inc. GST)

RIVCLINCH® P50 PASS Series - New one arrived Oct 2024

Recommended air pressure 4 to 6 bar 58-87 psi

Max. authorized air pressure 6 bar 87 psi

Min. working air pressure 4 bar 58 psi

Hydraulic pressure at 6 bar air pressure 350 bar 5’078 Psi

Clinching force at 6 bar air pressure 50 kN 11 klb

Work stroke 8.0 mm 0.31"

Approach stroke 52 mm 2"

Total stroke 60 mm 2.36"

Cycle time 0.7-0.9 s

Max. sheet metal thickness,

mild steel, total 4.0 mm 0.16''

Max. sheet metal thickness,

Stainless steel, total 3.0 mm 0.09”

Max. sheet metal thickness,

aluminium, total 4.0 mm 0.16”

Recommended oil quality,

hydraulic circuit ISO VG 32

Noise level with booster

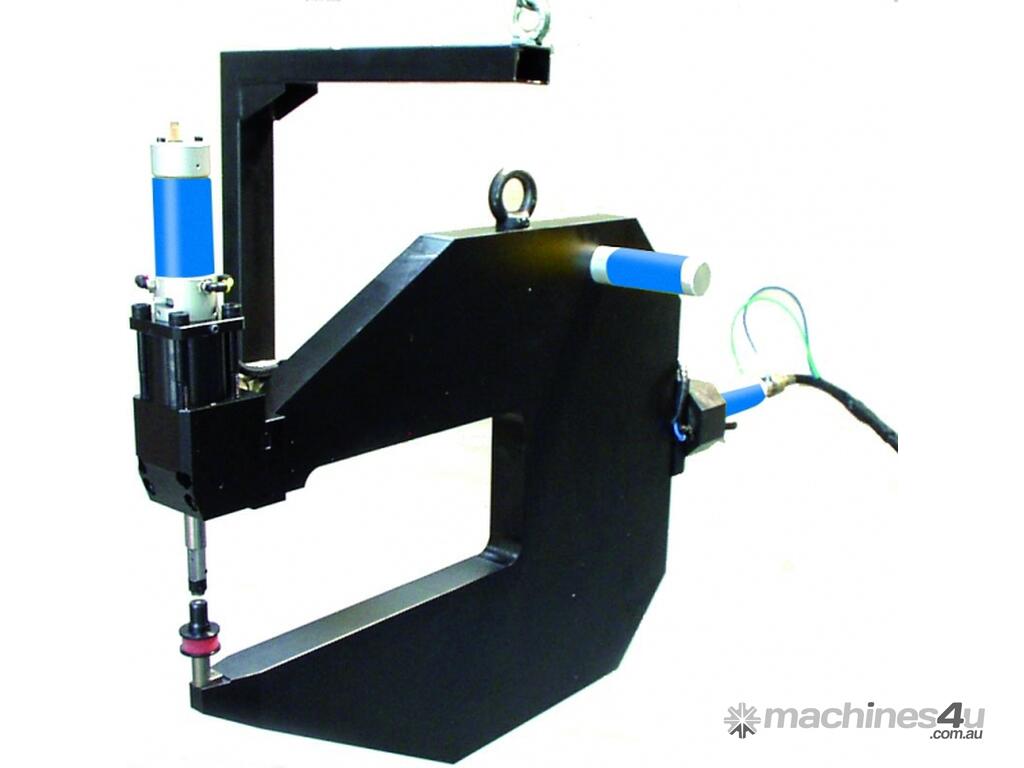

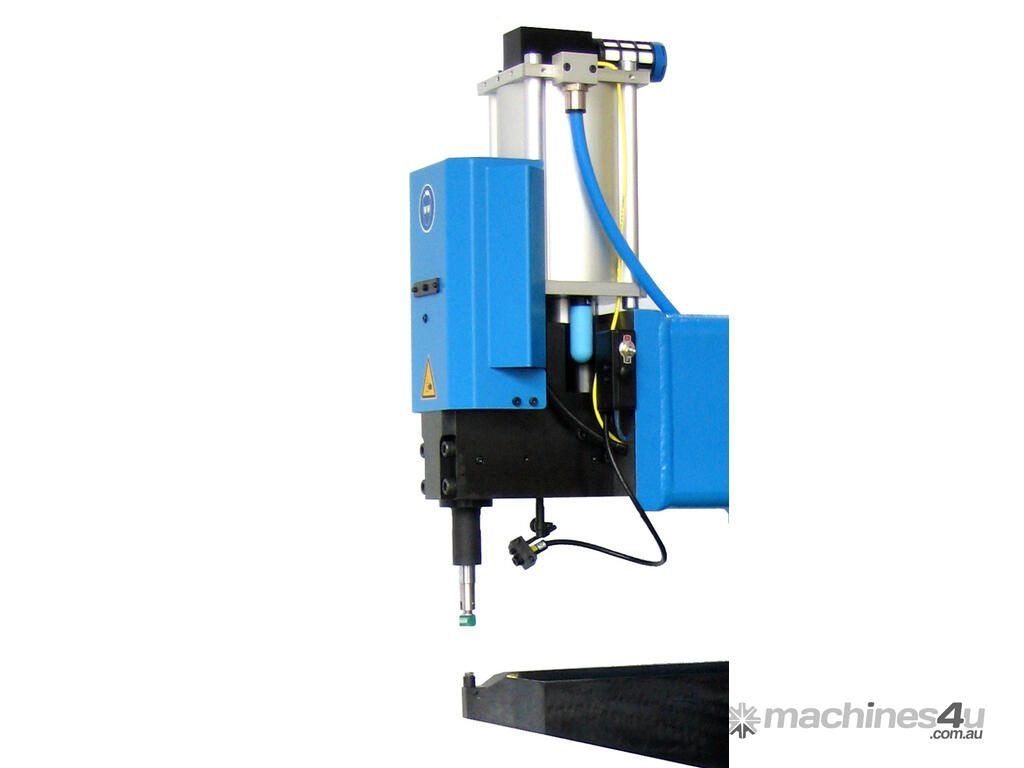

Ref. Fig. 1

Support, workhead and booster (pressure intensifier).

Optional equipment:

Tool kits: various combinations of dies and punches of type SR503 OR SR603

Functional description

Single-stroke clinching, opening die

The clinching method used by this RIVCLINCH®

machine is based on a single-stroke

method, patented or patents pending world-wide by Bollhoff Attexor S.A.

1. In the first part of the process, the punch will deform the overlapping sheet

material plastically inside a die cavity. The wall of the die, typically split in two,

three or four parts, remains closed.

2. When the lower material sheet reaches the anvil, i.e. the bottom of the die cavity,

the material will flow laterally and take a mushroom shape. In this phase the die

parts will be pushed outwards, sliding on a base. After the punch has been pulled

back and the die disengaged, the die walls will close again, pulled together by a

spring.

The result is a high-quality joint in terms of shape, strength and reproductibility.

A later section will explain how the cycle described above may be optimized.

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print